The ASME code or EN code we choose the materials and combinations best suited to individual performance needs. Thermac Pillow Plate Heat Exchangers For wider range of applications.

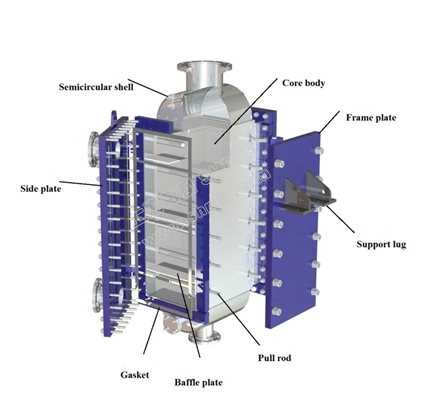

Welded Plate And Shell Heat Exchanger Coowor Com

The normal maximum operating pressure for a plate heat exchanger is generally 16 bar for ASME-code units.

. These materials are also suitable for higher temperatures up to 93C. You can simulate the plate heat exchanger perfect for your needs any time of the day from anywhere. ASME units require ASME relief devices per UG-125 of ASME Code Section VIII Div.

For shipment of shell-and-tube heat exchangers for the petroleum petrochemical and natural gas industries. Fizza453 Mechanical OP 20 Mar 17 1214. The manufacturer or his agent must be registered with the National Board.

Access the URL below and click on the Web-Simulator icon. Customers can also request ASTM 5454EN AW 5454. Q U AF T LMTD 1 where.

State that to the best of my knowledge and belief the Manufacturer has constructed this plate and frame heat exchanger in accordance with ASME BOILER AND PRESSURE VESSEL CODE Section VIII Division 1. From -270C to 750C. Che-327 heat and mass transfer operations plate type heat exchanger design group members.

The six most important parameters include. If necessary to help for selection of Plate. H for plate heat exchanger is often in between 2 to 7 kWm 2 K -1.

Further data can then be determined. And frame heat exchanger conform to the ASME BOILER AND PRESSURE VESSEL CODE Section VIII Division 1. Alara melisa aydin coŞku moler resky saputra metu 25052016 ankara turkey 2.

Liquid to Liquid Heat Exchangers was developed for plate and frame heat exchangers because many applications in commercial HVAC systems were designed with very close. Due to the difficulties induced by the geometry and flow complexity an approach through a. Due to the difficulties induced by the geometry and flow complexity an approach through a.

A pressure vessel design code alone cannot be expected to cover all the special features of heat exchangers. Full Fit Gaskets Sealer Sigma M35 Heat Exchanger Gaskets With Indentification Tap. However plate heat exchangers which can operate at pressures up to 25 bar are available.

Plate type heat exchanger design 1. Plate Heat Exchanger Design. Anyone knows other codes standards of plate and frame heat exchanger used for downstream servicesrather than API 662 please help me.

1 Preventing Excessive Pressure. 1-11 Results for plate heat exchanger design code from 11 Products. But its the code for Plate heat exchanger used for offshore service.

Of Process Equipment Design PLATE HEAT EXCHANGER SELECTION SIZING AND TROUBLESHOOTING ENGINEERING DESIGN GUIDELINES Page 6 of 97 Rev. To give guidance and protection to designers manufacturers and purchasers a supplementary code is desirable. Equation 946 can also be applied to the situation of heat removal from a bioreactor for the purpose of temperature control.

The Plate Frame Heat Exchanger shall be designed and tested to the latest ASME Code Sect. Finally the relation for heat transfer is as relation 1. The codes cover all aspects of the construction of heat exchangers except the types of service loads other than pressure and the thermal design.

23 STEP 3. 1 report to department of chemical engineering middle east technical university for course. 1 11 w io h w c U t rr h k h 2 where.

AHRI 400-2001 with Addenda 1 and 2. U is defined as below. Depending on the design code applicable to pressure vessels ie.

H overall heat exchange coefficient kWm 2 K-1 S area of the heat exchanger m 2 ΔT ml K The value of S can thus be calculated as a 1st approximation of the heat exchanger size. All Vahterus heat exchangers are designed with the required design codes such as. Thanks Ankur for the answer.

The amount of heat to be transferred heat load. The pillow shaped design of the Thermoplates consist of two metal plates that are completely welded along the sides allows for optimal flow with sufficient turbulence for excellent heat transfer while minimising pressure drop. Ive searched around and found BP GS 126-5 Anyone needs this code PM me.

To solve a thermal problem we need to know several parameters. Full vacuum to 150 bar. ASME Boiler and Pressure Vessel Code Section.

64 DESIGN PRESSURE Operating a plate heat exchanger above its. Calculating the number of plates required. 02 Rev 02 Feb 2020 These design guideline are believed to be as accurate as possible but are very general and not for specific design cases.

In an effort to study and optimize the design of a plate heat exchanger comprising of corrugated walls with herringbone design a CFD code is employed. This API standard is applicable to heaters condensers coolers and reboilers but not. Plate heat exchanger calculation method.

T co T ci Q ˆ M ˆ c C p c T co 15 C 815 10 5 J s 1 694 kg s 1 419 10 3 J kg 1 C 1 430 C. In an effort to study and optimize the design of a plate heat exchanger comprising of corrugated walls with herringbone design a CFD code is employed. A is the heat transfer surface area Fis a correction coefficient T LMTD is the mean logarithmic temper-ature difference and U is the overall heat transfer coefficient.

Design Pressure and maximum working temperatures shall be in accordance with project plans. A universally accepted code for shell and tube exchangers is TEMA 1988 which although designed to supplement ASME VIII can be used in conjunction. The exit cooling water temperature is 43C.

Due to this unique construction Vahterus Plate Shell Heat Exchangers can meet very demanding design conditions. Guidelines for the mechanical design material selection fabrication inspection testing and preparation. I found the Code Case 2766 it does not require any design calculations or proof testing for establishing the MAWP for gasketed plate packs provided all 6 conditions of CC2766 are met.

H h and h c are heat transfer coefficients of the hot. MAWP of other pressure retaining parts will govern the design. Heat transfer coefficient and design margin.

HISAKA Web-Simulator HWS Plate Heat Exchanger This is the rst plate heat exchanger design website opened on the Internet in the world. ISO 122112012 specifies requirements and gives recommendations for the mechanical design materials selection fabrication inspection testing and preparation for shipment of spiral plate heat exchangers for the petroleum petrochemical and natural gas industries. October 1 2012 - DS.

We can design and manufacture plate heat exchangers in compliance with ASME American Society of Mechanical Engineers standard.

China New Design Counterflow Plate Heat Exchanger China Plate Exchanger Design Plate Heat Exchanger Efficiency

Pengiriman Gratis 40 Piring Brazed Plate Heat Exchanger 316 Stainless Steel Bahan Wort Chiller Aliexpress Peralatan Rumah

How To Crack Gasketed Plate Heat Exchanger Design

Brazed Plate Heat Exchanger Wort Chiller Bahan Stainless Steel 316 60 Piring Pembuatan Bir Chiller Sesuatu Yg Bersahajai Wort Chiller Onderdil Pompa Air Panas Aliexpress

Abx Brazed Plate Heat Exchangers

Mechanical Design Of Heat Exchangers

China Tp Fully Welded Plate Heat Exchanger For High Temperature And High Pressure Factory And Manufacturers Shphe

0 comments

Post a Comment